Top China Rapid Prototype Suppliers: Revolutionizing Metal Fabrication

As industries evolve, the demand for quick, efficient, and precise manufacturing solutions has skyrocketed. In the realm of metal fabrication, one pivotal innovation has emerged: rapid prototyping. China, with its unmatched manufacturing capabilities, stands at the forefront as a significant player in providing top-notch rapid prototyping services. This article delves into the intricacies of China rapid prototype suppliers and examines how they are reshaping the landscape of metal fabrication.

Understanding Rapid Prototyping

Rapid prototyping is a streamlined approach to creating physical parts using computer-aided design (CAD) software. It enables businesses to produce prototypes quickly, test ideas, and iterate designs without lengthy lead times. This method not only accelerates product development but also significantly reduces costs associated with traditional manufacturing processes.

Why Choose China for Rapid Prototyping?

China has emerged as a leading hub for rapid prototyping due to several key factors:

- Cost-Effectiveness: Labor and manufacturing costs in China are often lower than in Western countries, allowing for budget-friendly prototyping solutions.

- Advanced Technology: Chinese suppliers invest in the latest technologies and equipment, ensuring high-quality output and rapid production times.

- Skilled Workforce: China boasts a large pool of skilled engineers and technicians with expertise in various fabrication techniques.

- Efficiency: The streamlined processes followed by Chinese manufacturers ensure fast turnaround times, which are crucial in today's fast-paced market.

Key Processes in Rapid Prototyping

Understanding the processes involved in rapid prototyping is essential to appreciate the capabilities of China rapid prototype suppliers. Here are the most common methods used:

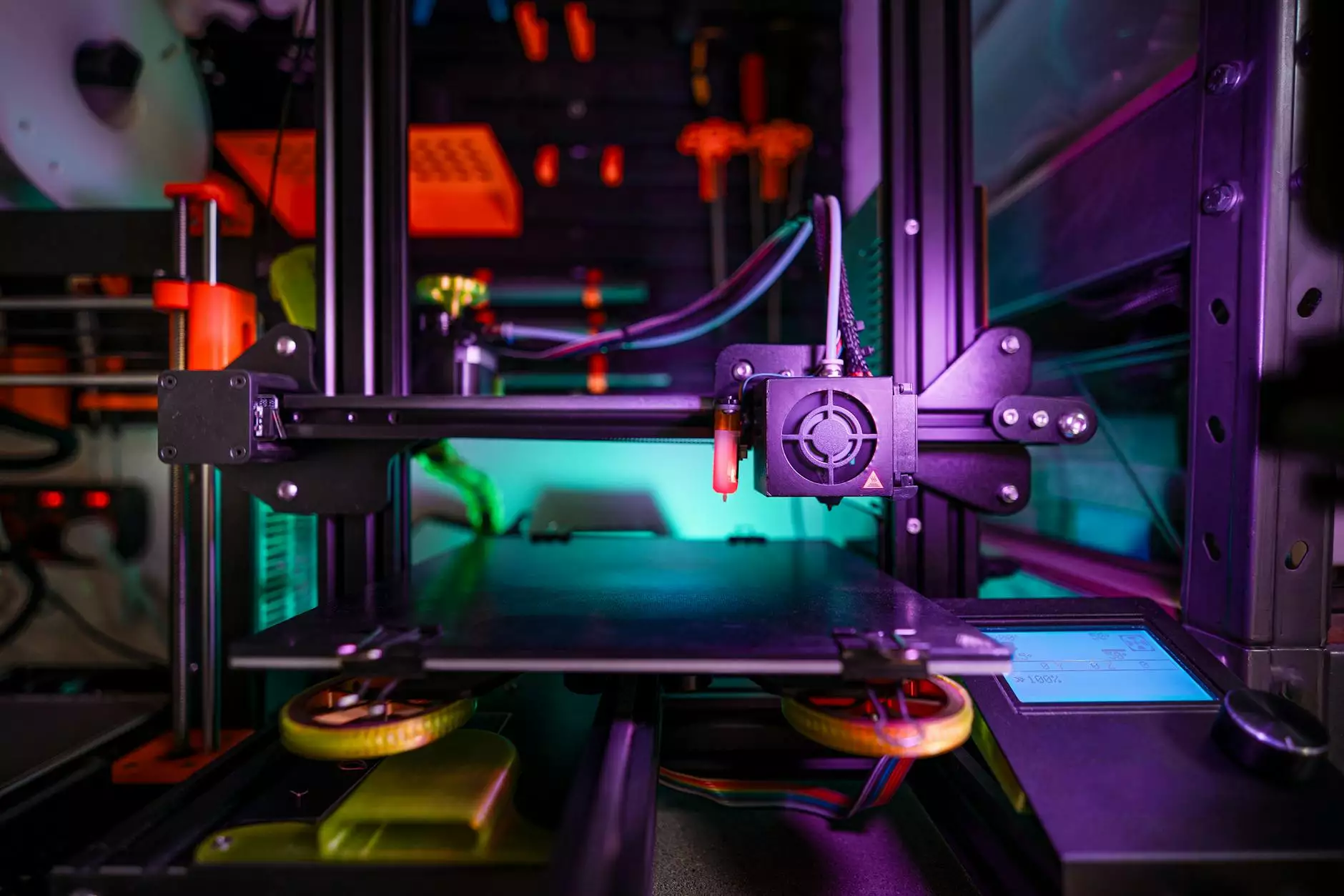

1. 3D Printing

3D printing, or additive manufacturing, is one of the most popular rapid prototyping methods. It allows for:

- Complex Designs: Create intricate prototypes that would be challenging to achieve using traditional manufacturing methods.

- Material Variety: Utilize a wide array of materials such as plastics, metals, and composites, making it versatile for different projects.

- Fast Production: Quickly turn CAD models into tangible items within hours or days.

2. CNC Machining

Computer Numerical Control (CNC) machining is another significant process where computer software controls machine tools. Its benefits include:

- Precision: Achieve tight tolerances and complex geometries required in metal fabrication.

- Material Flexibility: Work with various metals and plastics, enhancing design freedom.

- Scalability: Easily transition from prototyping to full-scale production while maintaining quality.

3. Injection Molding

Injection molding is typically used for higher quantities and is advantageous in rapid prototyping for:

- High-Volume Production: Once a prototype is validated, it enables the mass production of parts efficiently.

- Surface Finish: Provides excellent surface quality, which can be critical depending on the product requirements.

Choosing the Right China Rapid Prototype Supplier

With numerous suppliers available, selecting the right China rapid prototype supplier is crucial for your project's success. Here are some factors to consider:

1. Quality Assurance

Ensure the supplier has a robust quality control system. Certifications such as ISO 9001 can indicate a commitment to maintaining high standards.

2. Experience and Expertise

Look for suppliers with a proven track record in your specific industry. Their experience can guide you through materials, processes, and design challenges.

3. Communication

Effective communication is key to understanding your requirements. Choose suppliers who are responsive and comprehend your business needs.

4. Lead Times

Evaluate their production lead times. Fast turnaround can provide a competitive edge, so balance speed with quality.

5. Customer Support

A reliable supplier should offer excellent customer support, from project inception to delivery. This ensures that any issues are promptly addressed.

Case Studies: Successful Collaborations with China Rapid Prototype Suppliers

To demonstrate the effectiveness of choosing the right China rapid prototype suppliers, let's explore a few case studies.

Case Study 1: Electronics Startup

An electronics startup aimed to create a new gadget but faced challenges in developing a functional prototype. Partnering with a Chinese supplier that specialized in rapid prototyping allowed them to:

- Quickly iterate designs through 3D printing, which enabled testing of multiple configurations.

- Utilize CNC machining for parts that required high precision, ensuring all components fit within specified tolerances.

This collaboration cut their prototyping phase from months to weeks, allowing them to launch their product ahead of their competitors.

Case Study 2: Automotive Component Manufacturer

A company producing automotive components needed to refine their design for a new part. By engaging a Chinese rapid prototyping supplier, they were able to:

- Employ injection molding to create functional prototypes that closely mirrored the final product.

- Use feedback from the prototype tests to optimize their design before mass production.

As a result, the manufacturer reduced costs and improved the quality of the final product.

The Future of Rapid Prototyping in Metal Fabrication

The future of rapid prototyping, especially in the metal fabrication sector, is incredibly promising. Emerging technologies, such as metal 3D printing and advanced CNC machining techniques, continue to expand the possibilities of rapid prototyping. These advancements will lead to:

- Increased Customization: Manufacturers will be able to produce highly customized products that meet specific client needs.

- Eco-Friendly Practices: Enhanced processes will likely focus on sustainability, reducing waste in manufacturing.

- Integration with AI: Leveraging artificial intelligence in design and production will streamline processes further, allowing for smarter manufacturing solutions.

Conclusion

In conclusion, China rapid prototype suppliers are revolutionizing the metal fabrication landscape by providing cost-effective, advanced, and efficient prototyping solutions. Their expertise in diverse technologies like 3D printing, CNC machining, and injection molding creates unparalleled opportunities for industries seeking innovation.

If you are looking for a reliable partner in rapid prototyping, consider the factors discussed in this article, and explore potential collaborations that can elevate your manufacturing capabilities. Embrace this opportunity today, and lead your business towards a successful future with the help of experienced suppliers like those found at deepmould.net.